Today I revisited a property to take some equilibrium relative humidity readings in a hygrobox which I installed last week. The property is a new build which had floor screeds laid late last year. The clients are installing expensive oak flooring throughout and wanted to check the floors were dry prior to laying. I undertake these tests often for many flooring contractors and floor retailers across Yorkshire as no-body wants the responsibility of laying expensive floor coverings on floors/ screeds which aren’t dry. The client and contractor had been using the general rule of thumb for screed drying of 1mm per day, therefore envisaged it should easily be dry by now.

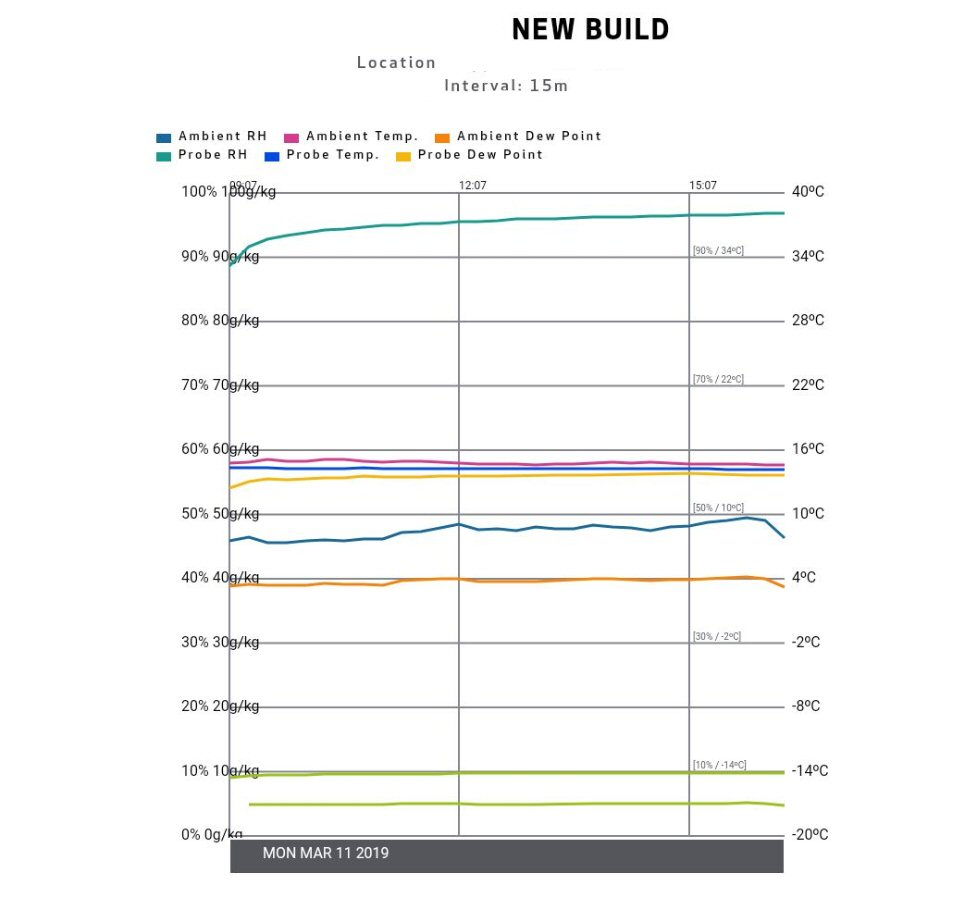

This particular screed is Anhydrite (calcium sulphate) and is around 60mm in depth incorporating under floor heating which has been on low shortly after it’s placing. Although the screed has been laid almost three months now, the conditions in the hygrobox were in excess of 90% ERH at 15 degrees. When the hygrobox was removed moisture was also present where the box was installed. Irrespective of the time the screed has been laid, the duration it takes for the screed to dry revolves around the atmospheric conditions. These figures of 1mm per day are judged on idyllic drying conditions at 20 degrees with low humidity levels. In a new build scenario however, this is rarely achievable as plastering, painting and other building practices undertaken after the screed has been laid all add more water to the atmosphere delaying drying further.

The answer is simple, before you consider laying expensive floor coverings always engage the services of a specialist to examine and check the floors moisture content. A few pounds spent in an assessment prior can save thousands of pound worth of replacement after.

Dryfix, There’s a reason we’re Yorkshire Leading Damp & Timber Specialists

Industry award winning company with the Property Care Association 2014, 2015, 2016 & 2018