So, you want to know the truth about moisture meters?……………………………. They don’t work, they don’t actually measure moisture, they’re designed for wood, they’re a waste of time, you can make them go red by putting your finger over them! Yes, during my 20 years in the industry and 14 years as a professional surveyor I’ve heard all the claims, even the suggestion that “rising damp is a myth” and doesn’t exist according to Jeff Howell.

There may be some truths in the above claims, however, these are often made by those who’ve read an article online, although, have no practical idea of how an electrical moisture meter works or even how to use one. The purpose of this article is to explore the claims and separate the myths from the facts, to explain the purpose of electrical moisture meters and why they are so popular in modern building surveying.

So how do moisture meters work?

Most electronic moisture meters have one or more various methods of testing which range from resistant probes, often called surface pins, capacitance pads or radio frequency sensors. Each one of these test facilities will provide a reading to the user, displayed either numerically usually expressed as a percentage of moisture or in a colour coded traffic light system, green for good and red for bad. Some units even do both.

To find out more about exactly how moisture meters work read our blog here:

https://dryfix.net/blog/electronic-moisture-meters/

So what do these numbers or colours actually tell us?

Well, that depends on exactly what material you’re testing. Most electronic moisture meters are calibrated for timber. As such, when you place the meter into wood the reading will be equivalent to the amount of moisture present in the wood material, this is a quantitative reading. The results will be expressed as a wood moisture content percentage, abbreviated to W.M.C (Wood Moisture Content). The meter works out the moisture content percentage by measuring the electrical resistance between two probes. Some electronic moisture meters can be calibrated for other materials such as concrete but for this article we’re just going to stick to wood calibrated meters.

So, If you use an electronic moisture meter on plaster or brick, what happens then?

Well, the moisture meter doesn’t know the difference in the material being tested, so it provides a reading all the same, assuming its all wood. When you interpret the reading however, you must consider the material you are testing. When testing masonry materials with a wood calibrated meter, the meter will still provide a reading although this should be interpreted by the user as an equivalent moisture value i.e. if this plaster were wood, it would have this much moisture in it (expressed as a percentage). The results will be written as Wood Moisture Equivalent W.M.E (equivalent value of moisture in the plaster if this were wood). An equivalent reading however, is not accurate or quantitative to the amount of moisture present in the plaster, it can’t be, as the meter thinks the plaster is wood and is only calibrated to understand moisture in wood.

Why bother using a wood calibrated moisture meter on masonry?

The meters, irrelevant of what material your measuring are still measuring electrical resistance, therefore, anything which increases electrical conductivity will cause the meter to fluctuate. Moisture or salts in walls will have the same effect, causing the meter to express a high moisture equivalent value, therefore, although the results may not be accurate in exactly how much moisture is in the wall, the fluctuation patterns can be recorded. This is often called profiling and is the process of establishing where these fluctuations emanate from and terminate to. Certain problems with damp display specific profiles, rising damp for example, will usually have a series of very high readings towards the base of the wall with a sudden drop off at the point of evaporation. Condensation will often have high readings only upon the surface of the plaster but very low readings beneath. Surveyors use the patterns irrelevant of them not being quantitative to the moisture present to aid in their diagnosis.

So how can you accurately diagnose how much moisture is in a masonry material with a wood calibrated moisture meter?

Well the truth is you can’t! You can only establish profiles of fluctuation to assume what is happening within the wall.

So why not just design a moisture meter for brick and plaster?

The problem with building materials, timber, plaster, brick and concrete is that they vary dramatically in their capillary makeup and ability to store / absorb moisture. In an ideal scenario, a surveyor would have an electronic moisture meter calibrated for each different material, however, this would require a vast array of separately calibrated instruments, not just one for brick and one for plaster but one for each type of brick and each type of plaster. Inevitably therefore, the above is unlikely to ever be practical. As such, we have a meter which is calibrated to be used on timber and provides a quantitative reading and when used on masonry it provides a wood moisture equivalent reading.

So, the claims are true, moisture meters don’t measure moisture?

If they’re calibrated for wood, they measure moisture only in wood. If they’re used on masonry they can’t measure moisture accurately, but they do have a purpose for establishing profiles.

If they can’t measure moisture in masonry accurately how can they be trusted to establish profiles accurately considering they respond to anything electrically conductive, like my finger?

Good question. A percentage of the diagnosis provided when an electrical moisture meter is used on masonry will be down to the skill of the surveyor.

There are other more accurate methods of testing for moisture, some based on site and others based off site, such as the calcium carbide meter often referred to as the speedy test and gravimetric testing. The problem with these inspection methods is that they are disruptive, therefore not often favourable in a pre purchase scenario. Not every client wants their house destroyed during the process of inspection. This is where electronic meters are often favoured.

There are other more accurate methods of testing for moisture, some based on site and others based off site, such as the calcium carbide meter often referred to as the speedy test and gravimetric testing. The problem with these inspection methods is that they are disruptive, therefore not often favourable in a pre purchase scenario. Not every client wants their house destroyed during the process of inspection. This is where electronic meters are often favoured.

As stated above, there is some truth in the claims that readings taken with an electronic moisture meter on masonry materials are not quantitative, instead they provide only a reading based on an arbitrary scale which is used to profile.

To determine exactly how accurate electronic meters are at profiling we designed a little experiment. During one of our surveys a property with typical rising damp symptoms was identified. This is an early 1900’s building without an original damp proof course, although, had benefitted previously from a retro-fit installation, in addition to replacement of the plaster. Despite this repair however, some years after the installation, the property continued to display symptoms of damp. Typical symptoms of rising damp were evident with salting and spoiling of the plaster finishes at low level and decaying skirting boards.

The right internal party dividing wall of the property was picked out from all other walls where it was established there were no other influences or contributions to the apparent dampness. When the surface plaster was tested with an electronic moisture meter both using surface pins and in radio frequency mode a typical rising damp profile was identified.

The right internal party dividing wall of the property was picked out from all other walls where it was established there were no other influences or contributions to the apparent dampness. When the surface plaster was tested with an electronic moisture meter both using surface pins and in radio frequency mode a typical rising damp profile was identified.

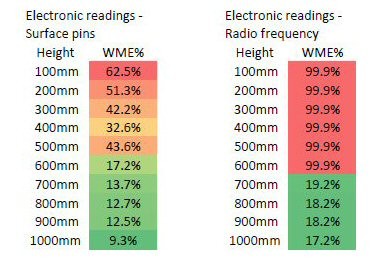

A full profile of the readings was undertaken from the surface plaster at 100mm increments from floor level up to 1m high. The graph below shows the results of the readings taken with both surface probes and in radio frequency mode, a typical rising damp profile with readings tailing off between 600mm and 700mm.

As mentioned above, critics could claim that these values are not representative of moisture within the structure, and the readings could be anything electrically conductive within the wall or plaster such as, salts or foil backed linings.

Agreed. Therefore, to further our experiment the surface plaster was removed exposing the brickwork and mortar joints. Samples were then also removed from both the mortar bed joints and within bricks in 100mm increments from floor level to 1m high. These samples were then taken back to our laboratory for gravimetric analysis. Gravimetric analysis is widely accepted as the most accurate process to establish accurately how much moisture is present within a material. This process not only establishes exactly how much moisture is present, but also differentiates between free moisture and hygroscopic moisture, therefore separates the potential of moisture from salt contaminates.

Agreed. Therefore, to further our experiment the surface plaster was removed exposing the brickwork and mortar joints. Samples were then also removed from both the mortar bed joints and within bricks in 100mm increments from floor level to 1m high. These samples were then taken back to our laboratory for gravimetric analysis. Gravimetric analysis is widely accepted as the most accurate process to establish accurately how much moisture is present within a material. This process not only establishes exactly how much moisture is present, but also differentiates between free moisture and hygroscopic moisture, therefore separates the potential of moisture from salt contaminates.

The process involves placing the samples through a series of different environmental conditions and carefully weighing the samples at each stage to establish their moisture uptake or loss. This uptake or loss can then be converted to determine the percentage values of moisture present within the material.

As can be seen from the graph below, the results of the gravimetric testing also revealed a typical rising damp profile with high levels of moisture present within both the mortar and brick at low level which tail off between the heights of 600mm and 700mm above floor level. This is exactly the same profile established with the electronic moisture meter both using pins and in radio frequency mode.

As can be seen from the graph below, the results of the gravimetric testing also revealed a typical rising damp profile with high levels of moisture present within both the mortar and brick at low level which tail off between the heights of 600mm and 700mm above floor level. This is exactly the same profile established with the electronic moisture meter both using pins and in radio frequency mode.

As can be seen from the results, the level of hygroscopic moisture (HMC) is relatively low, thus, salts played very little part in the fluctuation readings taken with the electronic moisture meter and the property is suffering from high levels of capillary moisture towards the base of the walls.

Considering the above, although the electronic moisture meter (Protimeter) may not have provided accurate moisture values regarding the percentage of moisture present within the wall, it has however been very accurate in comparison to the results of the gravimetric test, in establishing the profile and distribution of moisture through the wall.

Due to the way electronic moisture meters work, it has been unable to accurately determine the quantity of moisture within the wall or distinguish between hygroscopic moisture and free moisture, the quantity or origin of salts. That however, is the purpose of a disruptive investigation such as gravimetric testing and salt analysis.

As an aid to surveying and for establishing profiles which can lead a knowledgeable and experienced surveyor to a diagnosis, an electronic moisture meter is an invaluable tool.

Electronic moisture meters are complex to understand and interpret, that is why in the hands of the untrained, misdiagnosis can inevitably occur. Providing that they are used by trained and qualified surveyors who know how to use and interpret them properly, they do provide a quick non-destructive investigation tool for moisture profiling.

At Dryfix our damp and timber reports are only undertaken by experienced and fully qualified surveyors who hold the National Qualification for remedial surveying C.S.R.T. awarded by the BWPDA / PCA, our industry body. This proves that our surveyors have been independently examined and tested, proving their extensive knowledge and expertise.

All of our surveys are carried out in accordance with The British Standards Code of Practice.

Our surveyors carry all the necessary diagnostic and inspection equipment onsite, including thermal imaging and fibre-optic cameras to examine hidden cavities, highlighting blockages and bridged damp proof courses. Salt analysis testing and equipment for in-depth moisture analysis of masonry walls and plaster is also available. Photographic evidence of our findings is recorded and included within our report, so you can be sure of correct diagnosis.

Our reports contain comprehensive advice of any problems identified and include our recommendations, specifications and costs for repairs, if necessary. Edited pictures along with category damage ratings are also included to assist your understanding about the urgency of any repairs needed.

Our reports are available in both printed media and/or converted into secure electronic Portable Documents (PDF) for email.

Suspect a Problem?

If you suspect a problem and require a survey, or need advice please Contact us.